Explore our facilities

The Georgia Tech Manufacturing Institute (GTMI) operates advanced shared user facilities, offering secure digital manufacturing, additive and subtractive processes, and large-scale production capabilities. These facilities support everything from concept development to pilot plant operations.

Advanced Manufacturing Pilot Facility

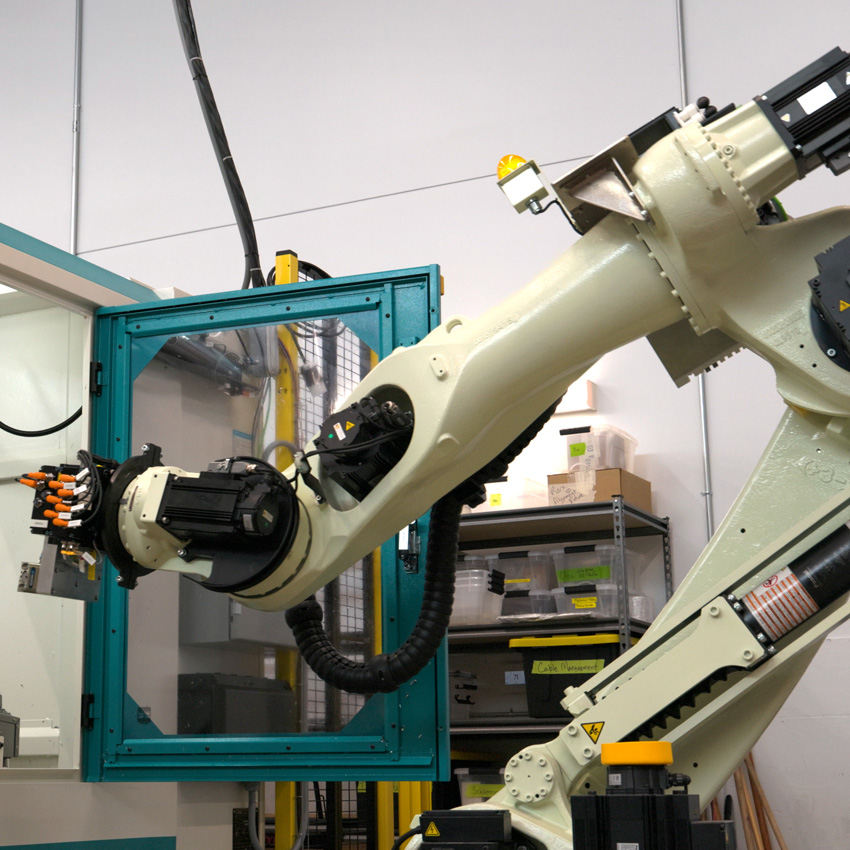

The Advanced Manufacturing Pilot Facility (AMPF) at Georgia Tech is the flagship facility of GTMI, where cutting-edge AI, robotics, and automation are shaping the future of advanced manufacturing. This state-of-the-art, 20,000 square foot research and development space is a dynamic hub where industry leaders, academic pioneers, and government innovators converge to transform early-stage concepts into groundbreaking realities.

AMPF Facilities

Hi-Bay Manufacturing Space

Bridging research and industry, GTMI’s high-bay integrates cutting-edge technologies — from metal AM and robotic WAAM to alloying and recycling systems. It’s a flexible, high-impact environment for developing, piloting, and scaling next-generation manufacturing processes.

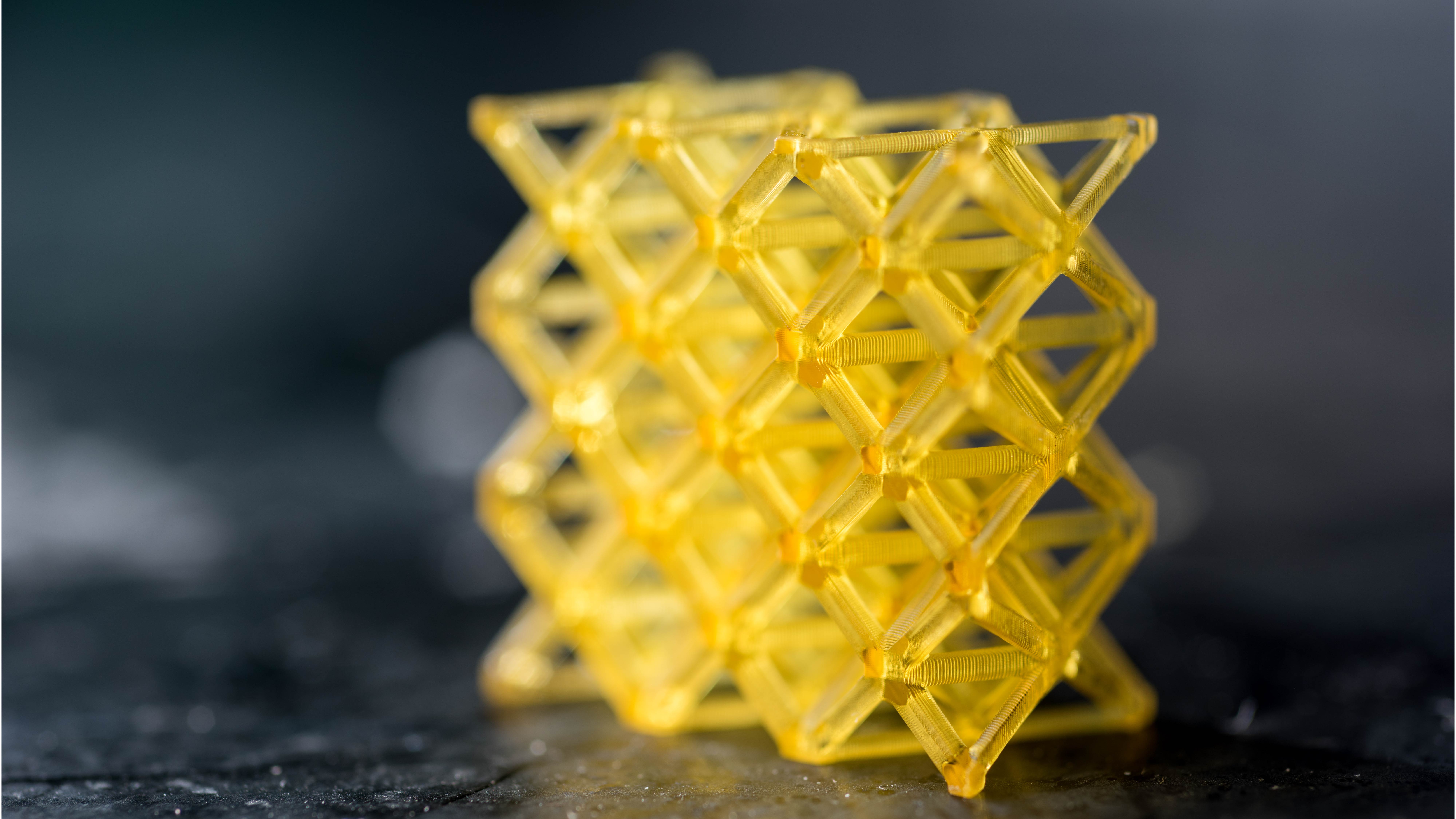

Additive Prototyping Lab

This lab specializes in advanced polymer and composites additive manufacturing techniques, enabling the creation of complex prototypes and parts with precision and efficiency.

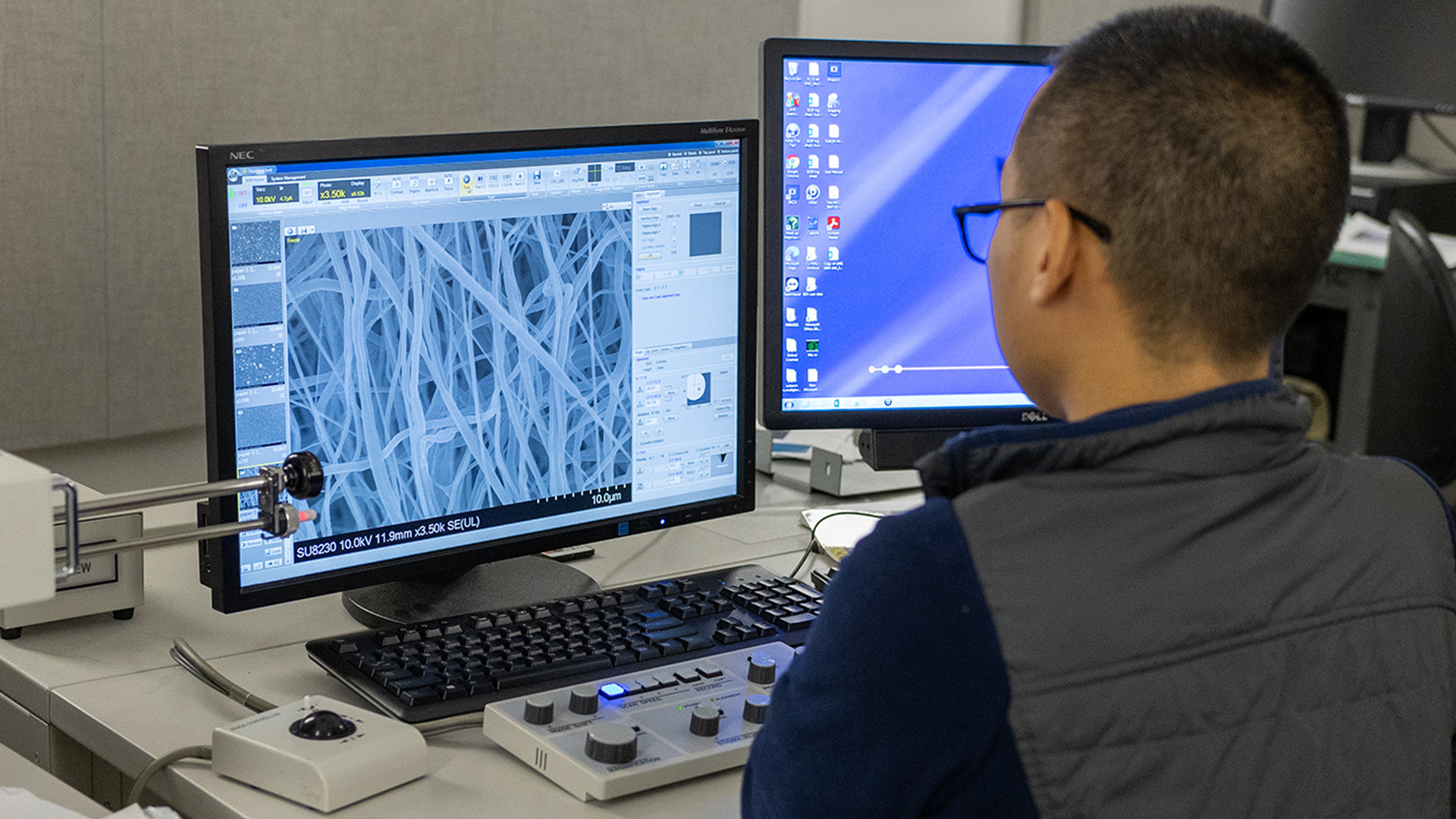

Characterization Lab

Operated in partnership with the Institute for Matter and Systems, this lab is equipped with state-of-the-art tools to provide high-quality materials analysis, ensuring the integrity and performance of developed materials. It features a full suite of metallographic sample preparation equipment from Pace Technologies, where users can dice, section, mount, grind and polish metal samples to specifications for all analytic requirements.

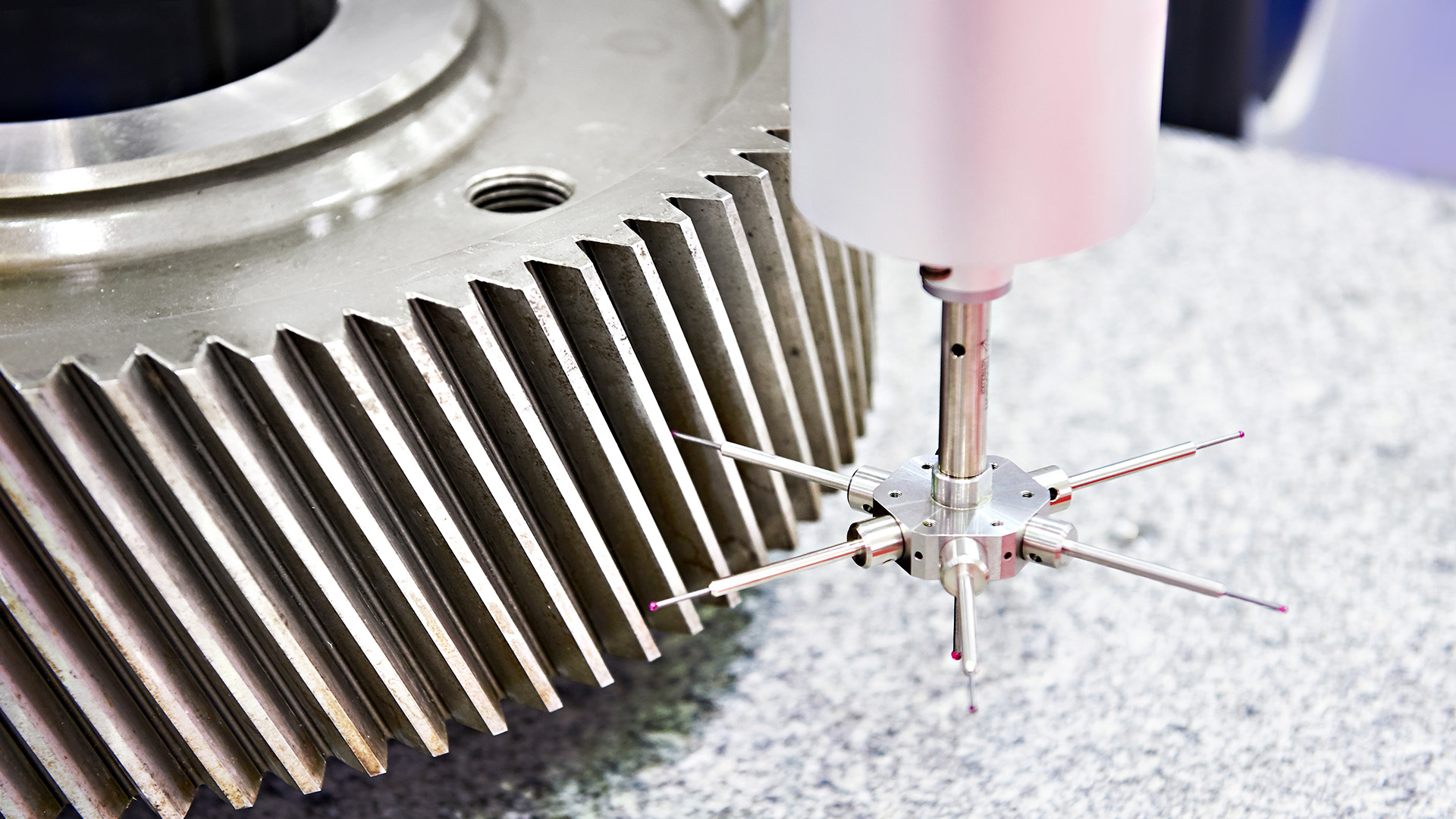

Metrology Lab

Focused on precision measurement and quality control, this lab ensures that all manufactured components meet stringent standards and specifications.

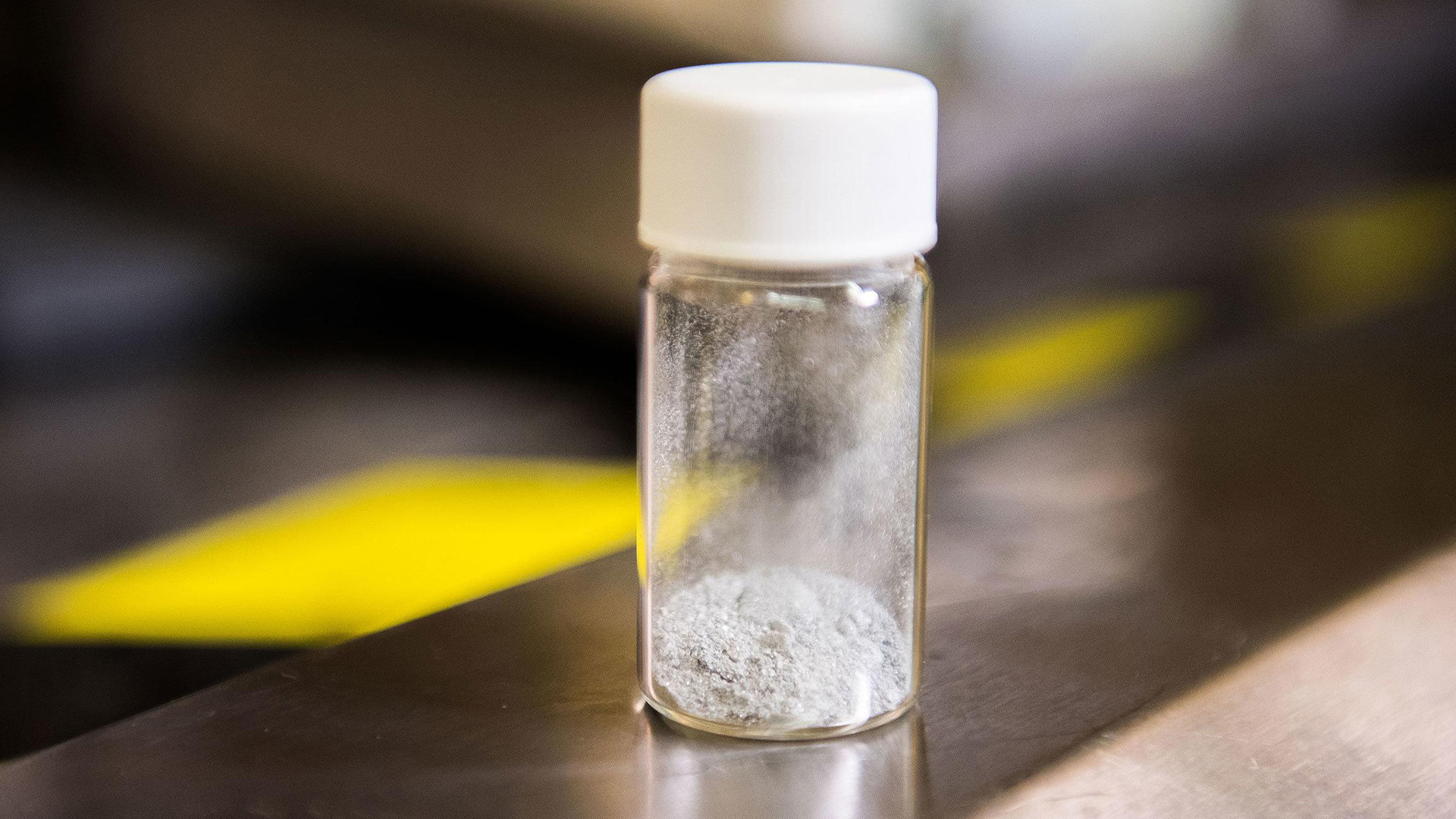

Synthesis Lab

Dedicated to the development of innovative materials and processes, this lab drives forward-thinking research and applications in manufacturing.

Featured AMPF Capabilities

Accessing the Advanced Manufacturing Pilot Facility

Schedule a visit to experience the latest in advanced manufacturing, automation, and next-gen materials innovation. Whether you’re an academic researcher, industry leader, or a startup, our team can help you succeed.

Learn more about how we’re manufacturing the future at ampf.research.gatech.edu or contact gtmi@gatech.edu to learn how to access our facilities. Whether you are a member of the Georgia Tech community or a non-GT affiliate user, there are only a few simple steps to join and gain access.

Coming Soon – Modular Pilot Scale Roll-to-Roll Manufacturing Facility

The Modular Pilot Scale Roll-to-Roll Manufacturing Facility at Georgia Tech is a state-of-the-art research and development space within the Georgia Tech Manufacturing Institute (GTMI). This facility is designed to support the scale-up of manufacturing innovations, making it accessible to academic, government, and industry partners worldwide.

Equipped with advanced roll-to-roll (R2R) manufacturing technologies, the facility transforms flexible substrate materials, such as paper, metal foils, and plastics, into complex, transportable rolls by coating them with various fluids like inks and solutions. These materials are then dried or cured to achieve the desired properties.

Key capabilities of the facility include:

- Flexible Electronics: Developing and scaling up the production of flexible electronic devices.

- Clean Water Technologies: Innovating and manufacturing advanced filtration and purification systems.

- Solar Cells and Batteries: Enhancing the production processes for renewable energy solutions.

- Material Coating and Deposition: Applying precise coatings to substrates for various industrial applications.

This facility serves as a testbed for proving advanced manufacturing techniques beyond lab-scale studies, facilitating the transition from basic research to commercialization. It plays a crucial role in advancing research, reducing costs, and increasing accessibility to cutting-edge manufacturing technologies.

Get notified

Want to know when this facility is online? Sign up for our mailing list.